Steel Plate Roll Fabrication And Welding under WPS/PQR/WQT follow up AWS D1.1 and ASME IX Code.

Pipe Work Fabrication

Extensive Experience in fabrication and assembly of Process Piping.

Process Piping

Welding Low Temperature Carbon Steels, 300 Series Stainless Steels, 22% Cr Duplex Steel, 25% Cr Duplex Steel, 6% Mo Stainless Steel and Cunifer, for both onshore and offshore applications.

Range of pipework qualification is ¼” to 48” diameter and 2mm to 60mm thickness. Qualifying codes include ASME B31.3.

In addition

- Facilities available on site for assembly,

testing and commissioning of equipment. - In-house Engineering and Draughting support

provided for projects. - Full 3D Autocad capabilities.

- Oil / Gas / Chemical Plants / CHP Plants.

- Paper and Board Plants.

- Cooling Water Systems (Hydro & Thermal).

Pipework / Fabrication Systems for

- NDT: Gamma radiography, X-ray, MPI, D/PEN and UT.

- Radiography Compound.

- Heat Treatment: Preheat and PWHT.

- Coating: Paint systems, galvanising and specialist coatings.

- Pressure Testing.

We also provide the following services through approved subcontractors:

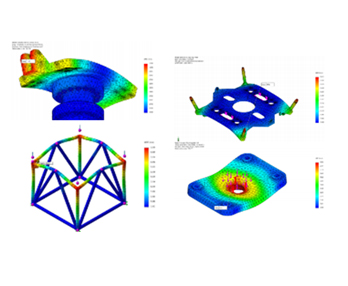

Structural Fabrication

We have Extensive experience in fabricating highly specialised structures and equipment from Mild Steel, High Strength Steel, Stainless Steel and Aluminium.

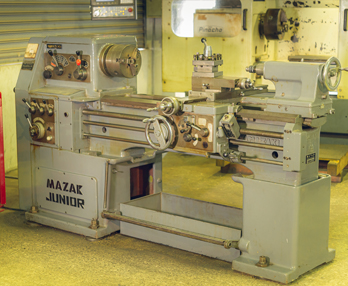

Hydraulic Equipment Manufacturing

We offer Hydraulic Equipment Manufacturing Services for Offshore and Onshore Projects.

Welding overview

Working to the global quality standards in welding. The facility has a large range of procedures and highly skilled staff built up over many years, allowing it to undertake critical tasks to suit every sub-contract welding project.

- A highly qualified team of Welding Technicians.

- All Welding Inspectors are qualified to CSWIP 3.1.

- A comprehensive suite of WPQRs/ WPSs to ASME IX and AWS D1.1

- Welders are qualified to ASME IX and AWS D1.1.

- A range of material welding capabilities including carbon steel, stainless steel and aluminum steel.

- Processes used include manual and semiautomatic welding using SAMW, GTAW (TIG), GMAW (MIG & MAG) and FCAW processes.